Calibrate Your Spreader

By the end of this publication, you will have learned how to check the distribution pattern of your spreader, determine the spreader’s effective spread width, and calculate the best application rate to most effectively apply your fertilizer.

DETERMINE AND ADJUST DISTRIBUTION PATTERN: CREATE SPREADER CALIBRATION KIT

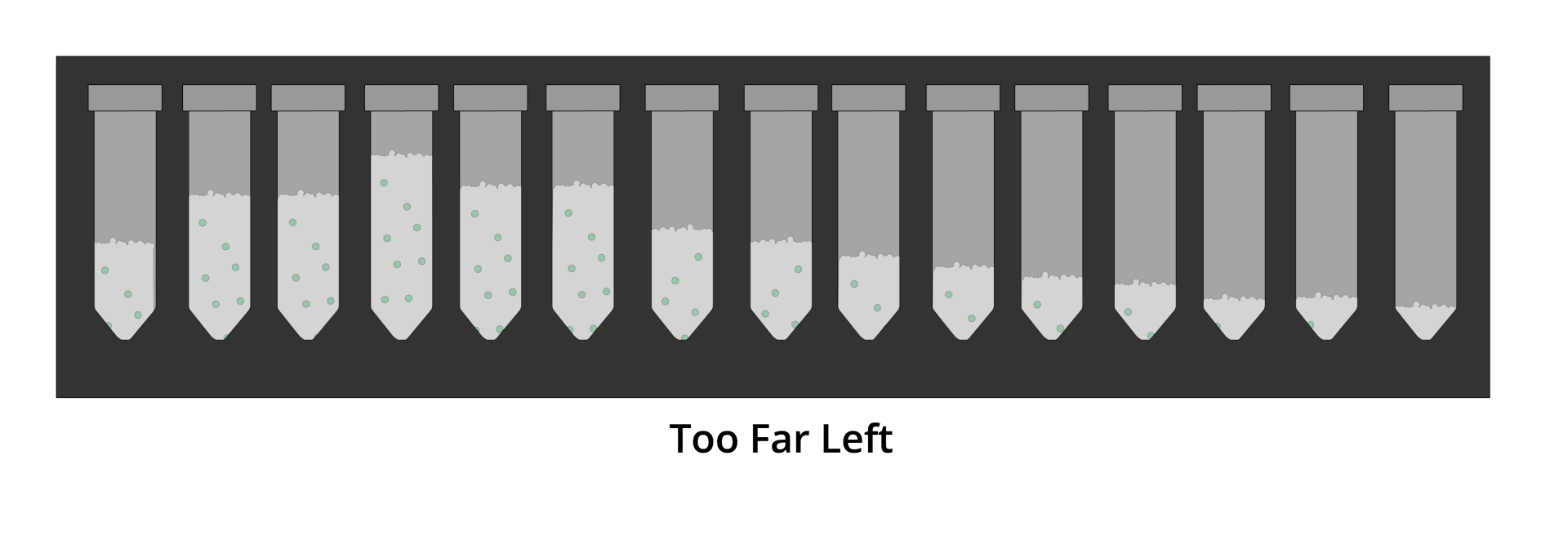

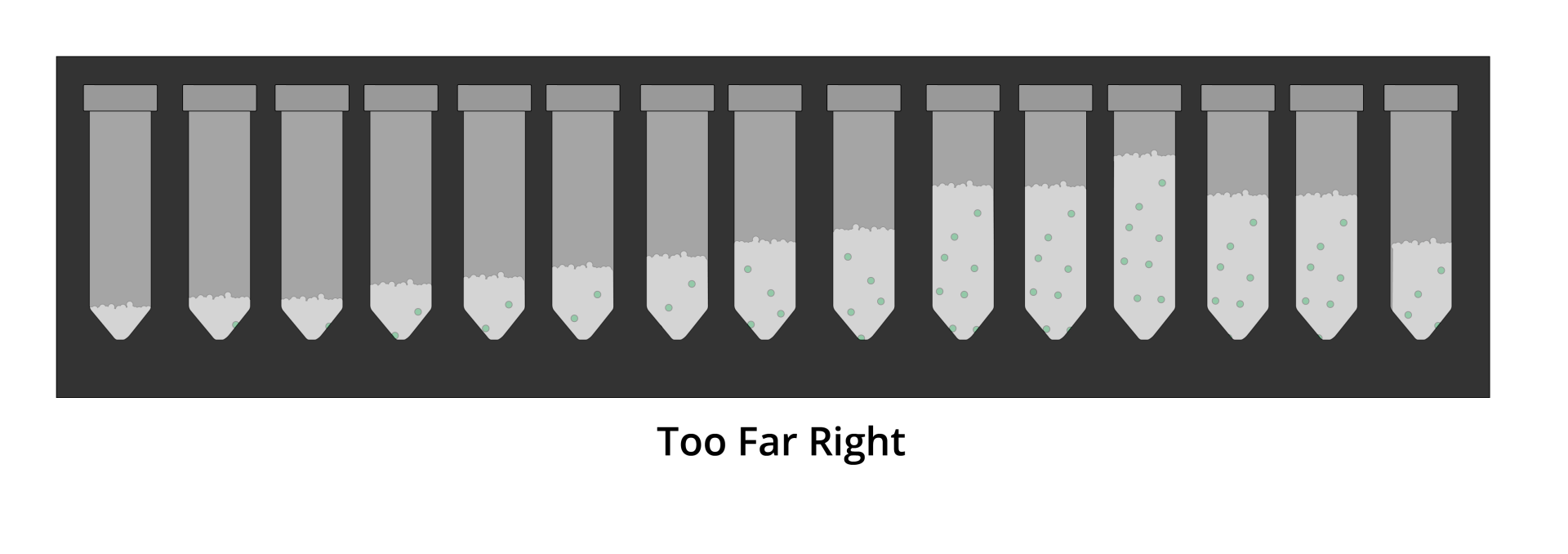

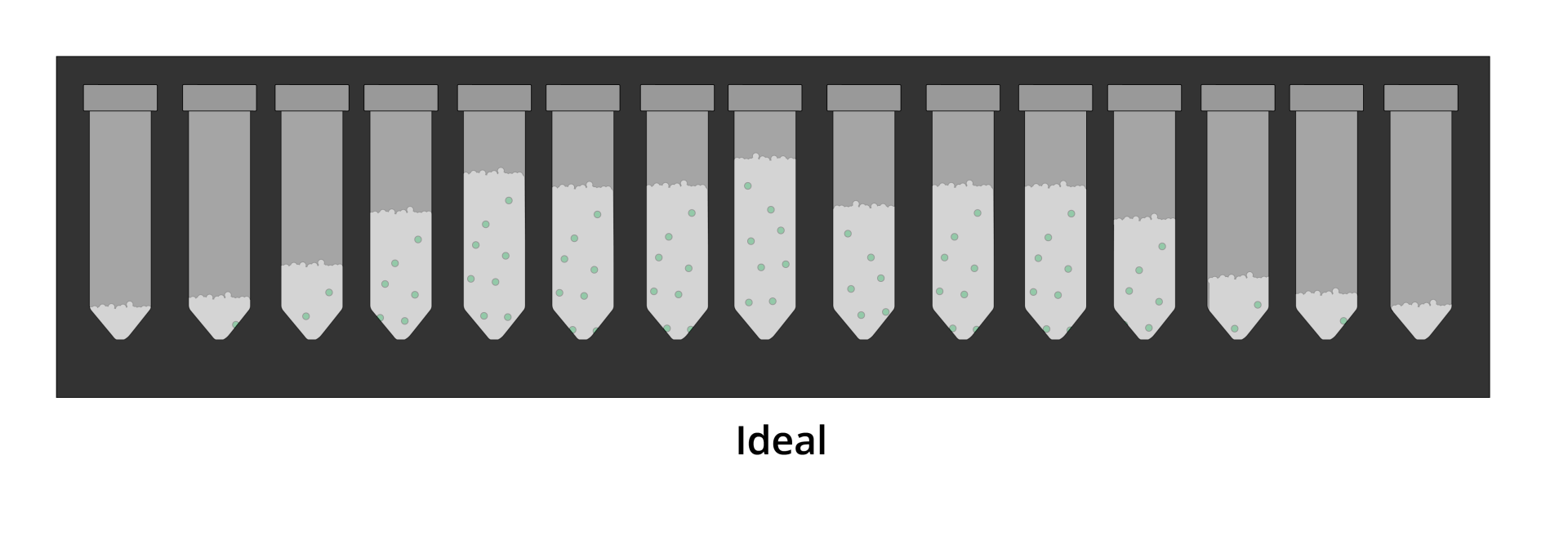

It is very important that the spinner plate distributes the fertilizer product evenly right to left because if one side gets more than the other, over application and turf banding/striping will occur. To determine the pattern of the spreader and get the most uniform application for your granular fertilizer, we must first create some pans for catching your fertilizer and determining the distribution pattern.

- Collect 11-15 boxes or pans - 1 X 3 ft in size, 2 inches deep. (11 boxes if your granules are small; SGN > 150, 15 boxes if your granules are large; SGN < 150).

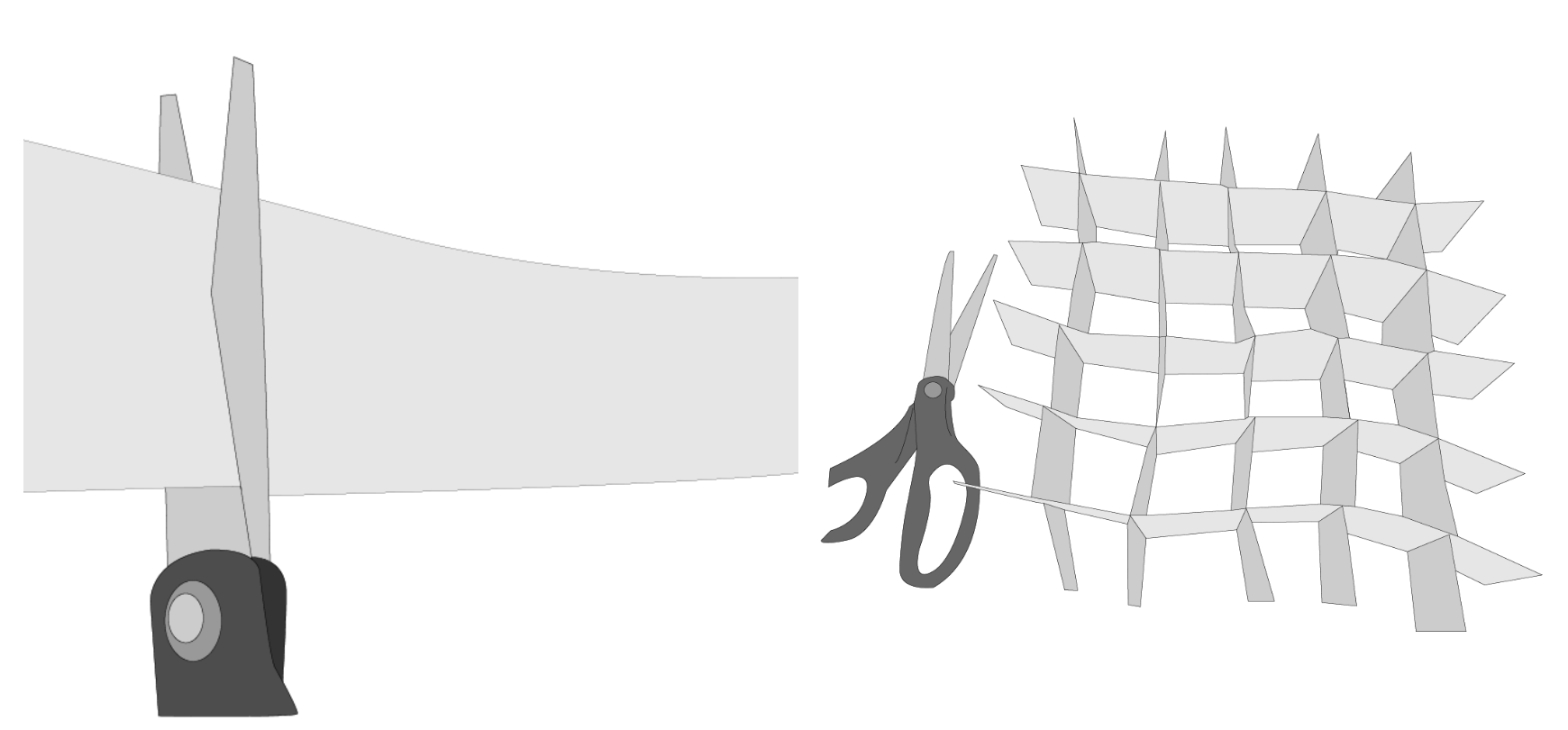

- Create paper baffles to prevent fertilizer from bouncing out of your box – for each box, cut 30 12 in x 2 in strips of paper, cut slits at 2 inch intervals (each strip should have 5 slits) fit 5 strips across 5 other strips together using the slits, 3 sets of 10 strips should fit in each box.

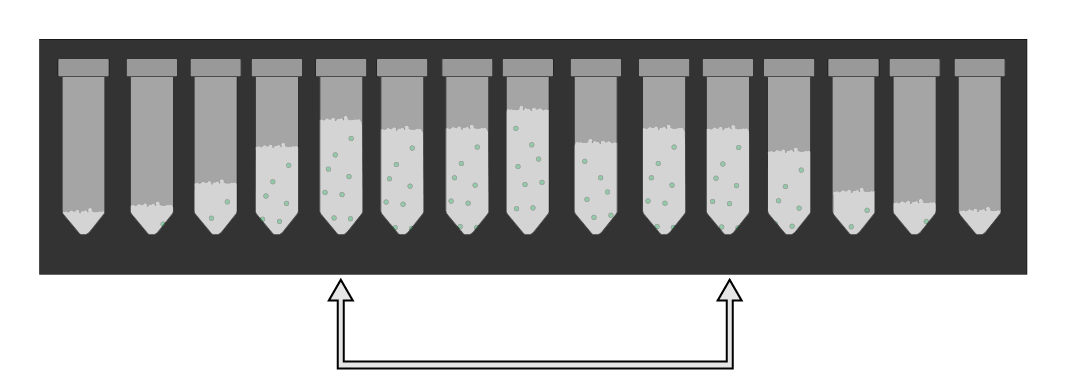

- Gather 11-15 (11 for small granules, 15 for large granules) clear containers to be used to measure each box’s contents, clear tubes are recommended, but clear cups can be used, please ensure each container can hold 1 to 4 fluid ounces.

- An optional rack/display is recommended to display your containers to assess the pattern efficiently.

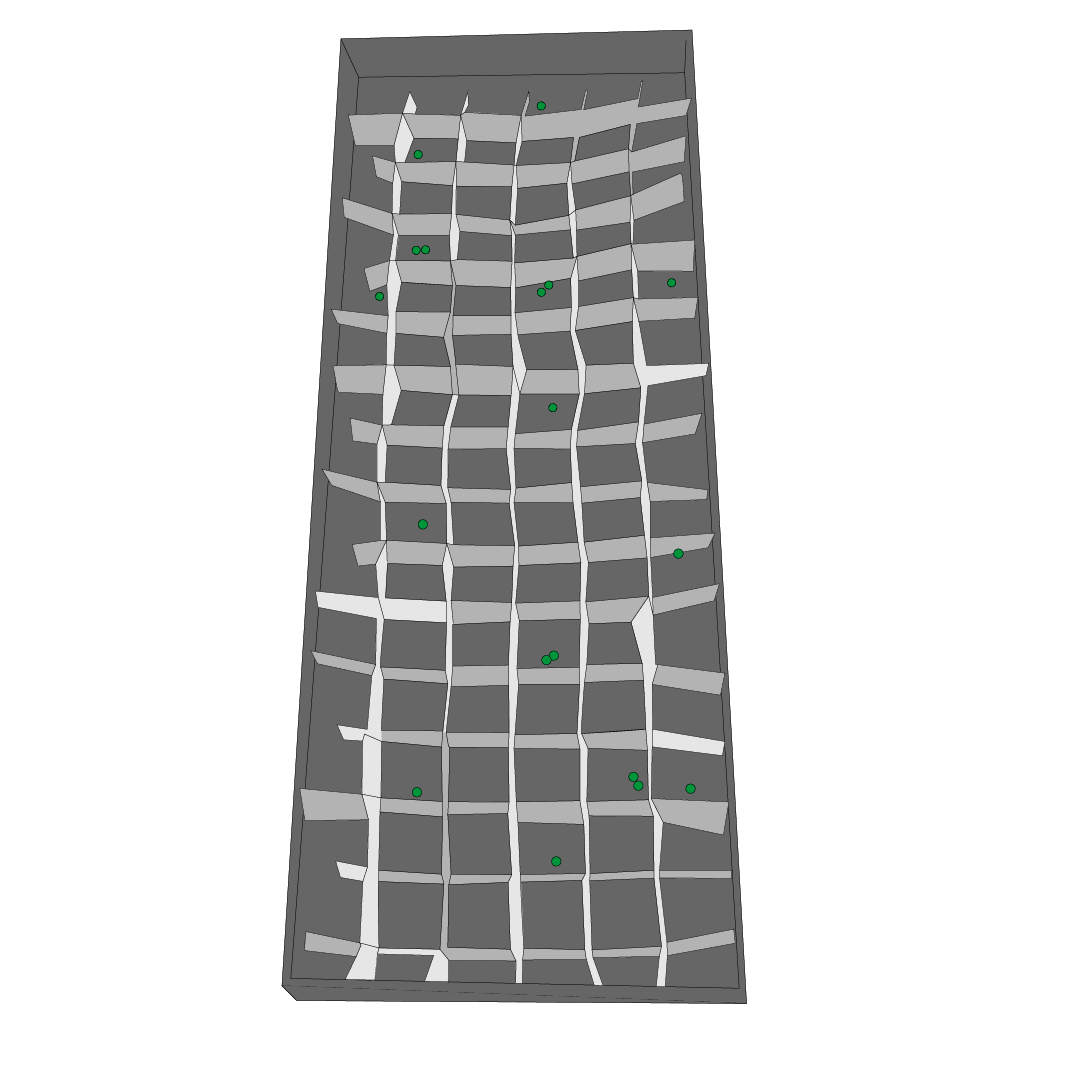

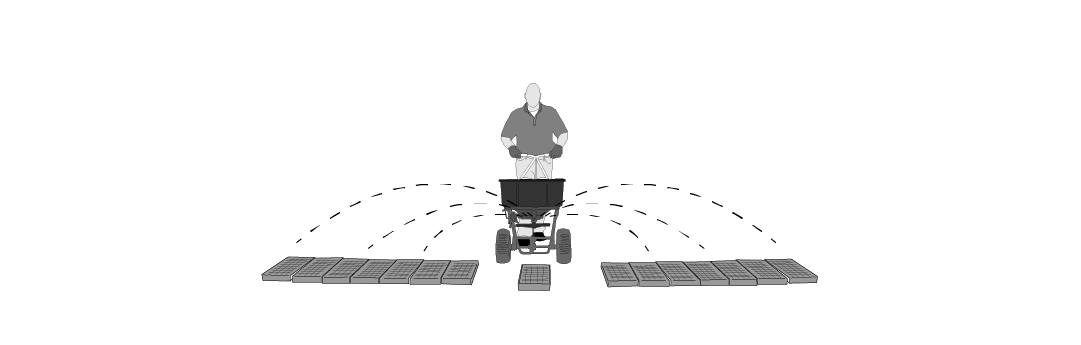

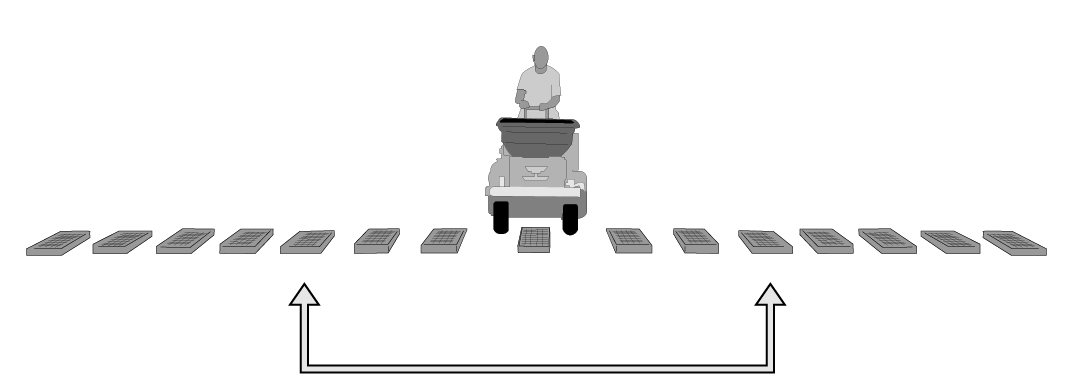

- Place boxes side-by-side in a line perpendicular to the spreader’s path. With one box in the middle for the spreader to pass over, there should be sufficient space on either side of the box for the spreader wheels to pass. One box in the middle and then equal number of boxes on both sides evenly spaced apart. Space the boxes up to 12 inches apart depending on the granule size and impeller speed.

- Choose a starting point for your application rate that is similar to your final rate setting, the fertilizer bag should have a suggested setting for your spreader.

- Set an estimate pattern adjustment, (ex. opening size of third hold adjustment, adjusting the sliding gate, or rotating the conical distribution device, depending on model/type of spreader). Initial adjustment is a starting point, further adjustments will be made until fertilizer distribution is uniform.

- Fill hopper at least halfway with fertilizer. Pass over the boxes several times. Note the spreader’s speed, gear, and RPM and any other control so you can maintain it consistently later during applications.

- Time to measure what we’ve collected in the boxes. After you pour the contents of each box into its corresponding container, make sure to leave the boxes in their original places, we will need to measure them later. Arrange the containers in the same pattern as their corresponding boxes, side-by-side, optionally on a tube rack, with the center box’s container also in the center. With all of the containers next to each other, it is easy to see the patterns of your fertilizer distribution and whether it needs adjusting.

- If necessary, adjust the spreader pattern adjustment setting and then repeat steps 4 and 5.

- First, of the collected product in containers, find the two containers on either side of the center container that have about half the product of the center container.

- Then, go to the box on the left side that corresponds to the container that collected half the product.

- Measure the distance between this box and the corresponding box on the right and mark it, that is your effective spread width.

CALCULATE AND APPLY THE PROPER APPLICATION RATE

- Determine the rate in which you want to apply your fertilizer per 1,000 sq. ft. How much nitrogen you need to apply per 1,000 square feet is your rate. For example, a 20-0-0 bag contains 20 percent of Nitrogen per pound. Divide the desired Nitrogen rate by the percentage of Nitrogen the product contains to get the amount of fertilizer to apply. (Ex. 1 lb / 0.20 = 5 lbs of fertilizer).

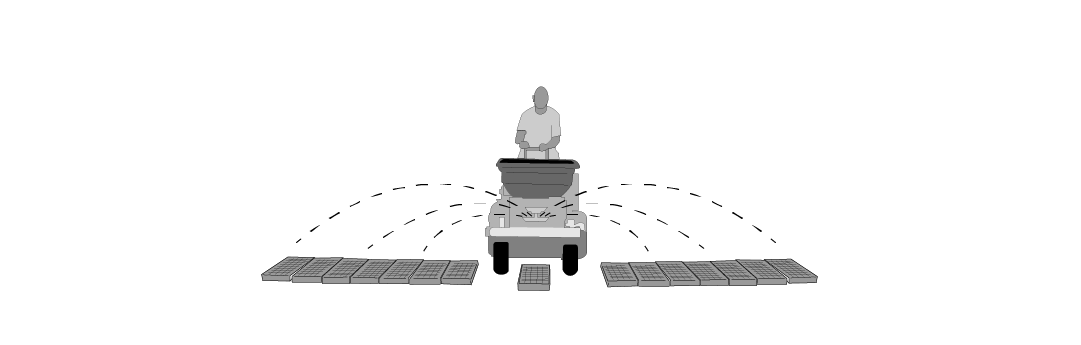

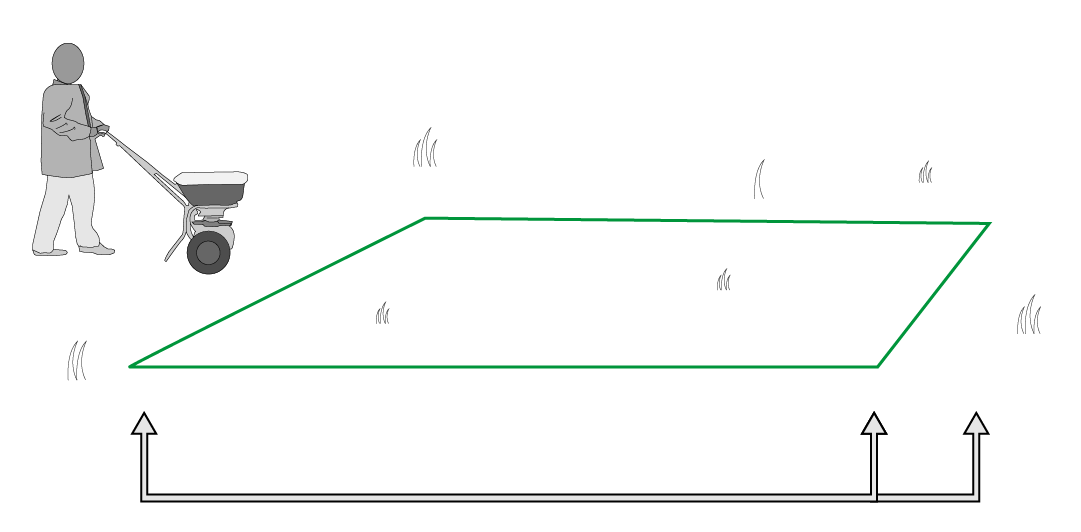

- Set the length of the calibration course by taking 1000 and divide by effective spread width (measured earlier) (Ex. 1000 ft2 / 11 ft = 91 ft. This means calibration course is 11 ft wide by 91 feet long), place markers at start and finish of calibration course.

- Set a gate opening, based on the fertilizer bag, manufacturer recommendations, etc. This is a starting point for rate calibration.

- Pour the whole bag of fertilizer into the hopper, or a measured amount, the important point is that the amount is exact.

- Apply the product over the calibration course, then use a clean and empty vacuum to vacuum the remaining fertilizer from the hopper and weight the amount. Subtract the empty weight of the bucket, and then how much fertilizer was left in hopper after course run. The total fertilizer amount should be subtracted by what was left in hopper, the remaining lbs is the rate of application. (ex: 25 lbs (total) – 20 lbs (in hopper) = 5 lbs per 1,000 square feet).

- Adjust spreader, if necessary. Repeat step 4 to 5 (to avoid lawn burning, don’t reapply to same calibration course).

- Record the speed, gear, RPM, impeller speed setting (if applicable) and gate opening for future reference.

To learn how to calibrate additional spreaders and sprayers visit:

https://ppp.purdue.edu/wp-content/uploads/2016/08/PPP-104.pdf

For professional fertilizers, humic and AMP-XC™ enriched products available, please visit TurfCare’s online Product Catalog.

For green industry professionals or others interested in ordering Turfcare products, please contact our Customer Service to find a distributor near you.

The TURFReport Highlights:

Additional Articles and Insights