January 30, 2026

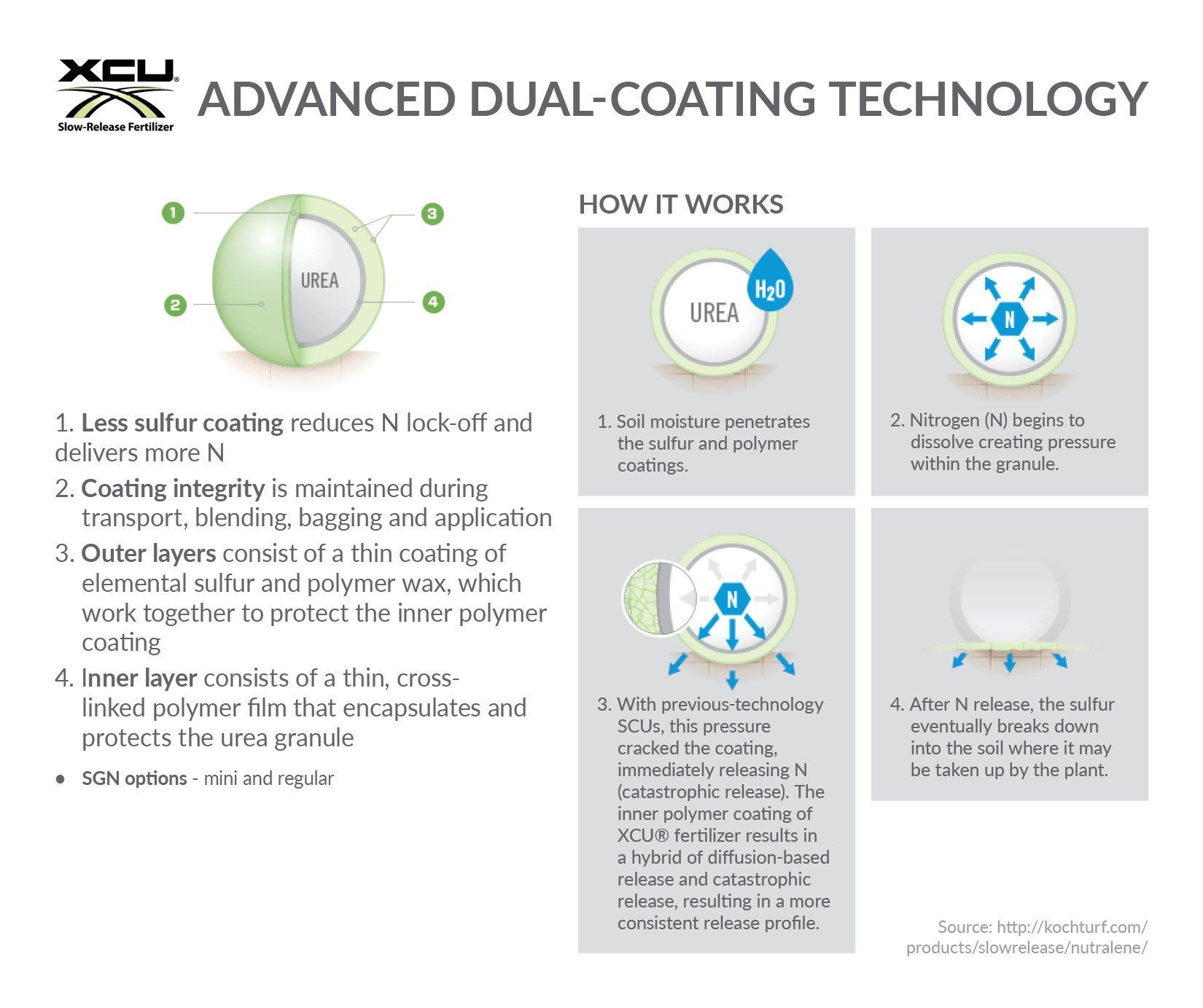

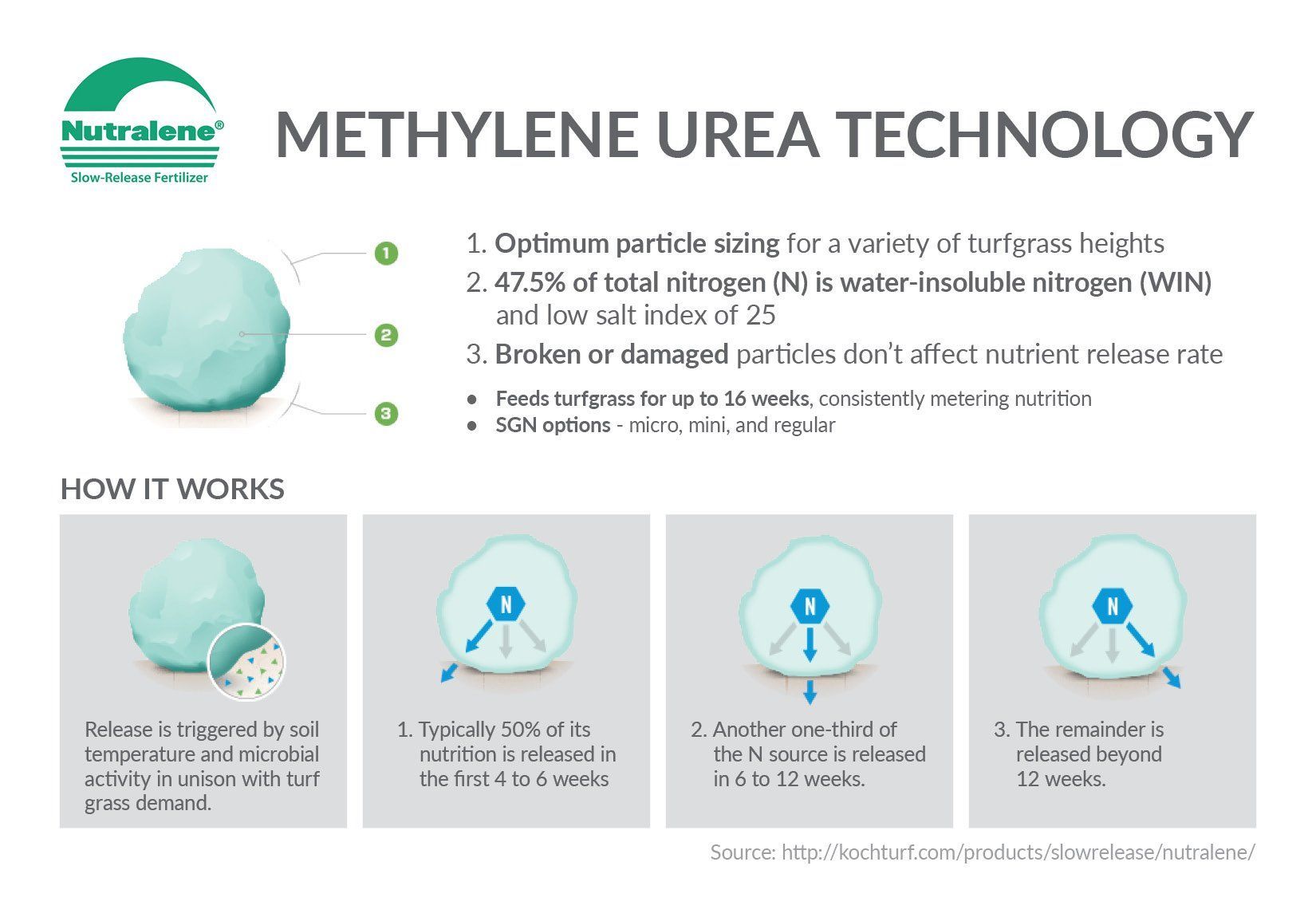

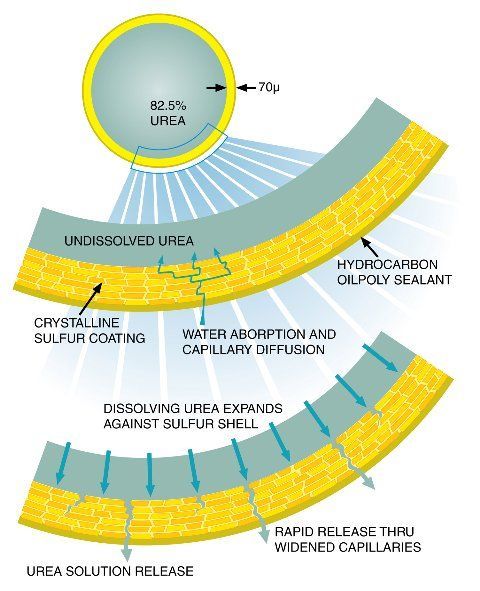

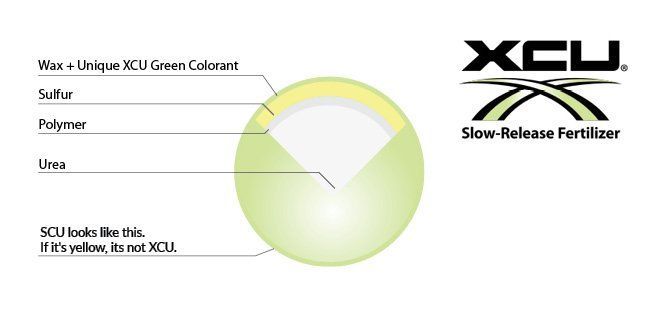

White Plains, NY – January 30, 2026 – Interoceanic Corporation (“IOC”) announced today that its affiliate Spring Valley USA (Spring Valley) , has acquired the blending and packaging assets and business of Turf Care Supply, LLC, a leading manufacturer and blender of turf and ornamental fertilizers as well as ice melt. The combination of Spring Valley and Turf Care Supply’s blending business, forms one of the largest independent lawn and garden fertilizer platforms in North America. The integrated business will have approximately 250 employees and will operate eight manufacturing and blending facilities across seven states, enabling coast-to-coast coverage of customers. By uniting two highly complementary companies, this acquisition creates a world-class turf & ornamental supply company positioned to deliver enhanced value to both professional and retail customers. “This acquisition is a transformative step for our organization,” said Elio Mazzella , President of IOC and Spring Valley. “By bringing Turf Care Supply into the IOC family, we are significantly expanding our reach and capabilities in serving the lawn and garden industry. The combined company will have an unrivaled production footprint and product portfolio, which means we can offer our customers faster service, greater efficiency, and innovative solutions on a national scale. Our goal is to build a world-class platform that blends the strengths of both businesses – the supply chain efficiencies of the combined business and the family-business values – will drive growth for our customers and vendor partners.” With the closing of the transaction, Turf Care Supply, LLC will be renamed Allied Nutrients and continue to manufacture leading enhanced efficiency fertilizers (“EEF”) out of its Martins Ferry, Ohio facility. Mark Mangan, President of Allied Nutrients, commented, “we want to thank our long-time employees that will be joining the IOC family and wish them well. We have known the IOC team for many years and believe this will be a great home. At the same time, we are excited for our remaining employees as we focus our resources and efforts on providing the best EEF solutions to the turf and ornamental market.” With this acquisition, the combined company now operates manufacturing facilities in Wisconsin, Ohio, Texas, Florida, Massachusetts, Tennessee, and Oklahoma, giving it the ability to blend and package fertilizer products and ice melt closer to customers in every major region. Turf Care Supply’s sites in Hatfield (MA), Sebring (FL), Cleveland (TN), and Catoosa (OK) will join Spring Valley’s existing plants in Jackson (WI), Fostoria (OH), Greenville (TX), and Longwood (FL). This expanded footprint significantly reduces transit times and enhances supply reliability for our customers. Maintaining strong customer relationships during and after the integration is a top priority. “All of our customers will continue to receive the outstanding service and product quality they expect, now with the added benefit of a truly national production network,” Mazzella added. Each major customer will be supported by an expanded team dedicated to ensuring a seamless transition and ongoing success. Strategically, the merger of Spring Valley and Turf Care Supply unlocks significant commercial synergies that will benefit both our customers and vendor partners. Together, the company will offer the most comprehensive product portfolio in the industry. “This combination is about building a platform that is perfectly suited to support our customers growth,” said Mazzella. “By combining our R&D and product development efforts, we intend to bring new, high-value solutions to market that neither company could have achieved alone.” The integration of the two businesses is already underway, with a focus on maintaining operational continuity and exceptional customer service throughout the spring season. The company also emphasized that all Turf Care Supply employees are being welcomed into the organization, and that the combined workforce will play a crucial role in driving the business forward. “This is an exciting moment for all of us. By uniting two great teams, we’re creating a stronger company with a shared commitment to our customers’ and vendors success, ” Mazzella noted. About Interoceanic Corporation (IOC): Based in White Plains, NY, IOC is a diversified family-owned company specializing in the production, marketing, and distribution of fertilizer and industrial chemical products. Other notable affiliates of IOC are PCI Nitrogen, Columbia River Nitrogen and EM² Enterprises. With this transaction, the group of businesses consist of over 600 employees. IOC’s family values, entrepreneurial spirit, and supply chain expertise have driven its growth from a regional fertilizer distributor into an international platform that provides reliable, high-quality products. About Allied Nutrients: Based in Brunswick, OH, Allied Nutrients specializes in providing enhanced efficiency fertilizers that support turfgrass and ornamental plant health. Through world-class manufacturing and research and development, the company offers a comprehensive portfolio of products, including SCU, PCU, PCSCU, reacted slow-release nitrogen, and urease inhibitors. These solutions are marketed under leading brands, such as XCU, TTRU, UFLEXX, UMAXX, Nutralene, and Nitroform.